Maximum Payload (kg):12/7

Reach (mm):1700/1500

Speed (m/s):0.5/0.4

Precision (mm):≤0.01/≤0.01

Operating Temperature (°C):-10 to +50

Electrical Supply (V):230/230

Operating Environment:Indoor, Robust Manufacturing Environments

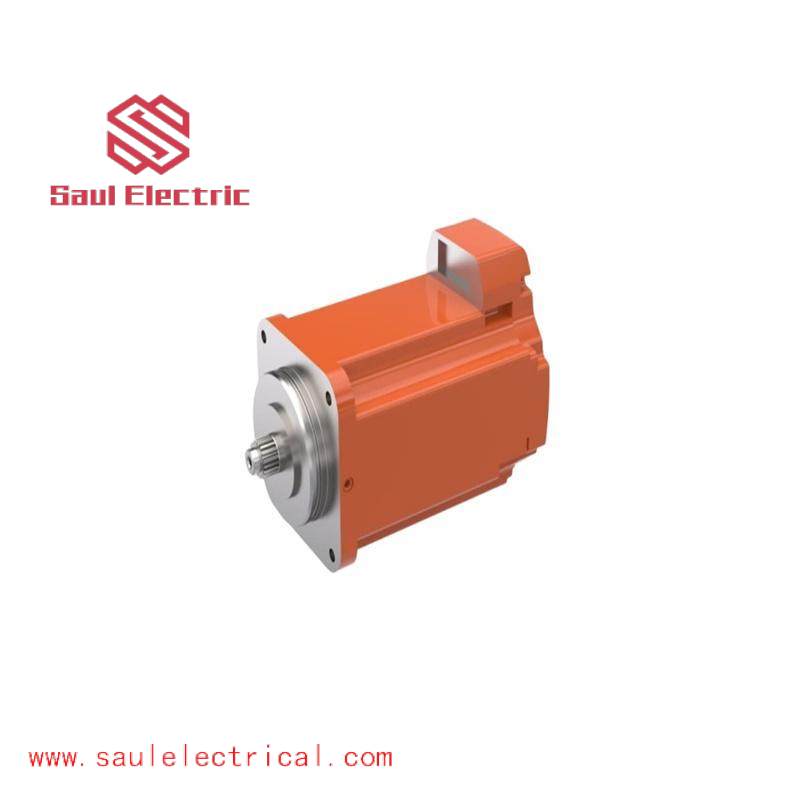

The ABB IRB7600 and IRB6640 series, enhanced with 3HAC062342-004 and 3HAC034863-005 models, are engineered to deliver unmatched performance in demanding industrial settings. With a payload capacity of up to 12 kg for the IRB7600 and 7 kg for the IRB6640, these robots are capable of handling a wide variety of materials and components with precision and efficiency.

These robots boast an impressive reach, allowing them to access and manipulate objects in areas previously inaccessible to conventional machinery. Their operational speed, reaching up to 0.5 m/s for the IRB7600 and 0.4 m/s for the IRB6640, ensures rapid and smooth movement, reducing cycle times and increasing productivity.

The precision of these robots is critical in applications requiring high accuracy, with a repeatability of ±0.01 mm, ensuring consistent quality in every production run. This level of accuracy is particularly valuable in industries such as automotive, electronics, and aerospace, where tolerances are extremely tight.

Designed for operation within a temperature range of -10°C to +50°C, these robots can withstand harsh conditions typical of manufacturing floors, enhancing their durability and longevity. The choice between single-phase or three-phase electrical supply (230V) provides flexibility for various installation scenarios.

Incorporating ABB’s latest advancements in control systems and software, these robots integrate seamlessly with existing production lines, facilitating easy setup and integration. They are also compatible with a wide range of accessories, including grippers, tool changers, and safety equipment, further enhancing their adaptability and application scope.

There are no reviews yet.