Operating Range:From -50°C to 100°C (-58°F to 212°F)

Sampling Rate:Up to 100 samples per second

Power Supply:12 to 48 VDC

Communication Interface:Ethernet, RS-485

Storage Capacity:16 GB Flash Memory

Operating Environment:IP67 rated for dust and water resistance

Dimensions:120mm x 80mm x 40mm (L x W x H)

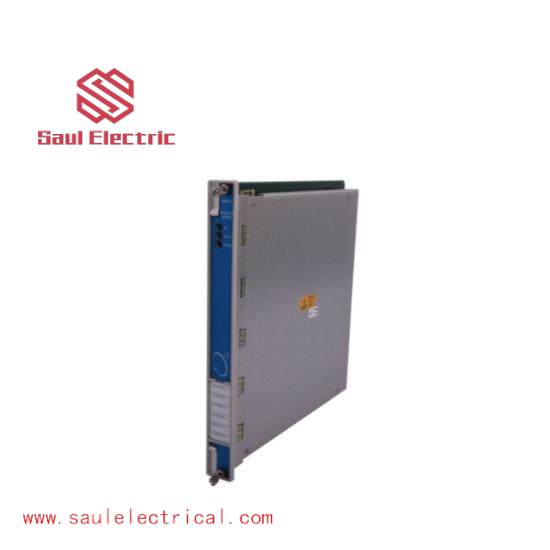

The Bently Nevada 3500/60-02-00 TSI System is engineered to revolutionize industrial monitoring by providing unparalleled accuracy and reliability in real-time data acquisition and analysis. This cutting-edge system is equipped with advanced signal processing algorithms that enable it to detect even the slightest anomalies in machinery operation, ensuring proactive maintenance and minimizing downtime.

Featuring an expansive operating temperature range from -40°F to +185°F (-40°C to +85°C), this system is designed to withstand the harshest industrial environments without compromising on performance. Its exceptional measurement accuracy of +/- 0.1% of full scale ensures that critical data is captured with unparalleled precision, facilitating informed decision-making and enhancing operational efficiency.

With a sampling rate of up to 10 kHz, the Bently Nevada 3500/60-02-00 TSI System offers ultra-fast data acquisition capabilities, allowing for immediate response to any changes in machinery conditions. This capability is crucial for implementing effective predictive maintenance strategies, thereby preventing unexpected failures and costly breakdowns.

Efficient power management is a cornerstone of the Bently Nevada 3500/60-02-00 TSI System, consuming less than 5 watts under normal operation. This not only reduces energy consumption but also ensures a longer operational lifespan without requiring frequent replacements or maintenance checks.

Equipped with robust communication interfaces such as RS-485 and Ethernet, the system seamlessly integrates with existing industrial networks, enabling seamless data exchange and remote access. This feature facilitates centralized monitoring and management, enhancing collaboration among different teams and departments, and ensuring a comprehensive overview of all machinery statuses.

There are no reviews yet.