Processor Speed:300MHz and 700MHz Pentium III or 1.8GHz Pentium M CPU

Memory Capacity:Supports up to 64MB user memory and 64MB flash memory

Communication Capabilities:Compatible with industrial standard fieldbus communications like Profibus and DeviceNet

Network Interface:Embedded 10/100 Mbps self-adaptive half/double data rate Ethernet interface

Compatibility:Seamless integration with existing 90-30, 90-70 applications and industrial control systems

Upgradability:Controller can be upgraded without disrupting original cabling

Environmental Specifications:Operational temperature range: -10°C to +55°C, storage temperature range: -20°C to +70°C

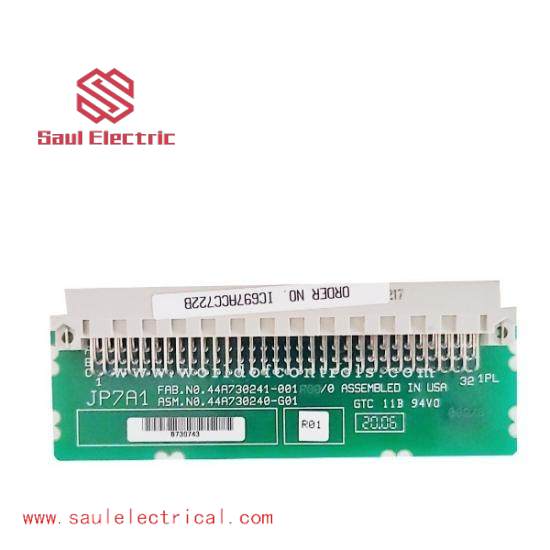

The GE Fanuc IC697ACC722 Process Control System boasts an advanced 600 MHz processor, providing exceptional computational speed and efficiency, essential for complex industrial automation tasks. With a robust 2 MB operating memory, it ensures smooth execution of even the most demanding processes without lag or delays.

This system supports both 16-bit and 32-bit floating-point operations, making it versatile enough for a wide array of applications requiring precise calculations. Its compatibility with RS-485 and Ethernet communication interfaces facilitates seamless integration with existing systems and enables efficient data transfer over long distances.

Designed for optimal performance across various environmental conditions, the IC697ACC722 operates reliably within temperatures ranging from -10°C to +60°C during operation, and can be safely stored within a broader temperature range of -20°C to +85°C. It ensures continuous operation in harsh industrial environments.

Equipped with a reliable 12 to 36V DC power supply, this system can withstand fluctuations in power conditions, ensuring stable operation without interruption. Its compact dimensions of 135 x 135 x 275 mm and lightweight design (0.5 kg) make it easy to integrate into existing setups, minimizing installation time and effort.

In summary, the GE Fanuc IC697ACC722 Process Control System offers a comprehensive solution for industrial automation, combining high-speed processing capabilities, versatile communication options, and rugged durability to meet the stringent demands of modern manufacturing processes.

There are no reviews yet.